Quality control guidelines

In the past, many social problems in the construction industry have always occurred in structural frameworks.

This is because architectural structures are highly specialized and it is difficult to notice structural abnormalities, and once they are covered with finishing, they are hidden and cannot be seen.

At TSUYOKU, we eliminate individualism in both design quality and on-site quality, and use strict guidelines to ensure quality control that reduces errors and variations.

Structural design is not the same no matter who does it

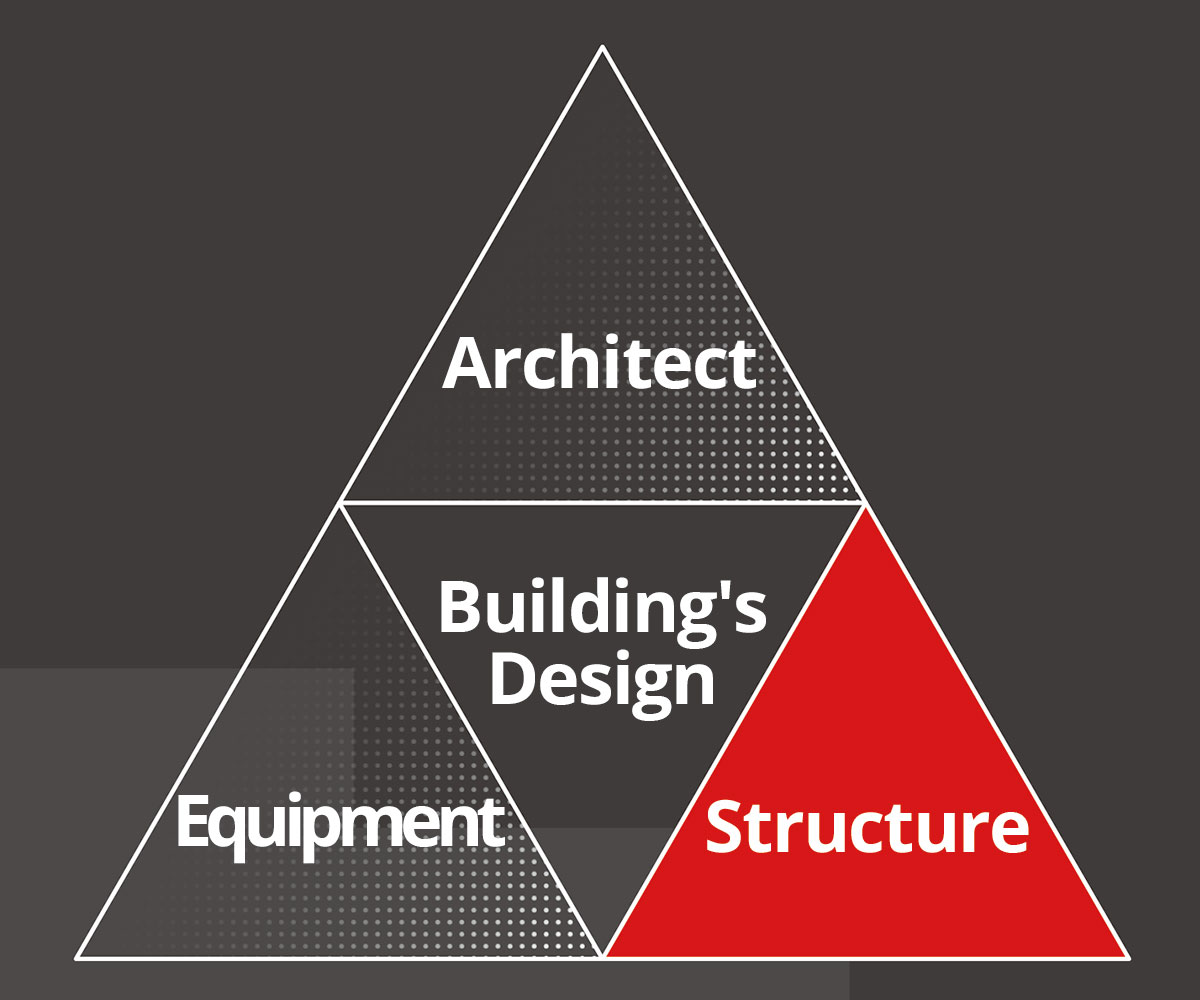

Building design is not all done by one person.

Generally, we proceed with the design by dividing it into three areas: Architectural design, Equipment design, and Structural design.

Architects design floor plans and building designs, and Equipment designers design air conditioning, acoustics, lighting, plumbing, etc.

Structural designers design the structural framework of a building (columns, beams, walls, floors, foundations, etc.) while ensuring the safety of the building.

Structural design tends to be thought of as simply calculating according to the law under given conditions, but there are many situations where different people make different judgments, as shown below, resulting in variations in results and quality.

- 1. Structural plan (column, beam, shear wall arrangement) is different

-

Will the structure be made of reinforced concrete or steel?

Whether to design with 12 columns or 11 columns…the decision will vary depending on the structural designer, and will greatly affect the result. - 2. The way the building picks up and applies the load is different

- The method of picking up the load differs depending on the structural designer, whether it is picked up roughly or based on the actual situation.

- 3. Modeling (stress calculation conditions) is different

- Modeling is the process of simplifying a building to make structural calculations easier. Judgements must be made based on various aspects such as setting the hardness of the components, how to insert slits, and other factors. It is also one of the tasks that has a large impact on the results.

- 4. Conditions for cross-sectional calculation are different

- There is more than one formula for calculating the cross-section of a column or beam. The structural designer will decide which formula to use.

- 5. Criteria settings are different

- Criteria such as live load conditions, sound insulation, seismic force, deflection/vibration, inter-story deformation, and building strength are determined in consultation with the client. Some structural designers set excessive criteria, either to improve efficiency or due to lack of communication.

Many of the past social problems in the construction industry have occurred in structural frames

In 2005, an incident occurred that shook the construction industry.

It is a case of falsification of structural calculations. To prevent recurrence, the Building Standards Act was revised, the building application procedure was changed, and the checking system for structural calculations became stricter. But still, problems continue to emerge.

The issue of falsifying steel frame accuracy inspection data at a major construction company that was discovered in 2023 is probably still big news in Japan.

Since deficiencies in finishing and equipment are likely to surface, there is a mentality of careful construction work.

Since the structural frame becomes invisible once it is covered with finishing, there is a risk that any mistakes made at the construction site will be hidden. Thus, making the on-site quality low.

Need for quality control guidelines

Against this background, major developers with a high awareness of quality control create their own company-specific specifications and ensure thorough quality control.

Architectural structure experts are now always involved in on-site supervision.

However, small and medium-sized developers do not have specifications and are unable to secure engineers, so they rely on the skills of structural designers and site supervisors, so the current situation is that there are hits and misses.

At TSUYOKU, we eliminate individualism in both design quality and on-site quality, and use strict guidelines to ensure quality control that reduces errors and variations.